Electropolished (EP) Seamless Tube

Chii chinonzi Electropolishing?

Electropolishingielectrochemical finishing process inobvisa chidimbu chechinhu kubva muchikamu chesimbi, kazhinji simbi isina tsvina kana alloys akafanana. Iyo nzira inosiya inopenya, yakatsetseka, yakanyanya kuchena pamusoro pekupedzisira.

Uyewo anozivikanwa seelectrochemical polishing, anodic polishingkanaelectrolytic polishing, electropolishing inonyanya kubatsira pakukwenenzvera nekubvisa mativi asina kusimba kana ane geometries yakaoma. Electropolishing inonatsiridza kupera kwepasi nekudzikisa kushata kwepamusoro kusvika pa50%.

Electropolishing inogona kufungidzirwa sereverse electroplating. Panzvimbo pekuwedzera jira rakatetepa reiyoni yesimbi inochajiswa zvakanaka, electropolishing inoshandisa electric current kunyungudutsa nhete yeioni dzesimbi mumhinduro ye electrolyte.

Electropolishing yesimbi isina tsvina ndiyo inonyanya kushandiswa kwe electropolishing. Electropolished Stainless simbi ine yakatsetseka, inopenya, yakanyatsochenesesa inopedza ngura. Kunyangwe simbi chero ipi zvayo ichashanda, simbi dzinowanzoitwa nemagetsi ndeye 300- uye 400-yakatevedzana simbi isina tsvina.

Kupedzwa kwe electroplating kune zviyero zvakasiyana zvekushandisa mumashandisirwo akasiyana. Zvikumbiro izvi zvinoda pakati pekupedzisira. Electropolishing inzira kuburikidza nekukasharara kweElectropolished Stainless Steel Pipe inodzikiswa. Izvi zvinoita kuti mapombi awedzere kurongeka muhukuru uye Ep Pipe inogona kuisirwa nekurongeka mumasisitimu akasimba senge maindasitiri emishonga.

Isu tine yedu yekupukuta michina uye tinogadzira electrolytic polishing machubhu anosangana nezvinodiwa zveakasiyana minda pasi pekutungamirwa neKorea tekinoroji timu.

Yedu EP Tube mu ISO14644-1 Kirasi 5 yakachena kamuri mamiriro, chubhu yega yega inocheneswa ne Ultra yakakwira kuchena (UHP) nitrogen uye yobva yavharwa uye yakapetwa kaviri. Certification inokodzera kugadzirwa kwetubhing, kuumbwa kwemakemikari, kuteedzera zvinhu, uye kunyanyisa kwepamusoro kuomarara kunopihwa kune zvese zvinhu.

Tsanangudzo

ASTM A213 / ASTM A269

Hushasha & Kuoma

| Production Standard | Mukati Hukasha | Kunze Kukasharara | Hurema max |

| HRB | |||

| ASTM A269 | Ra ≤ 0.25μm | Ra ≤ 0.50μm | 90 |

Relative Elemental Kuumbwa kweTube

Report 16939(1)

Process

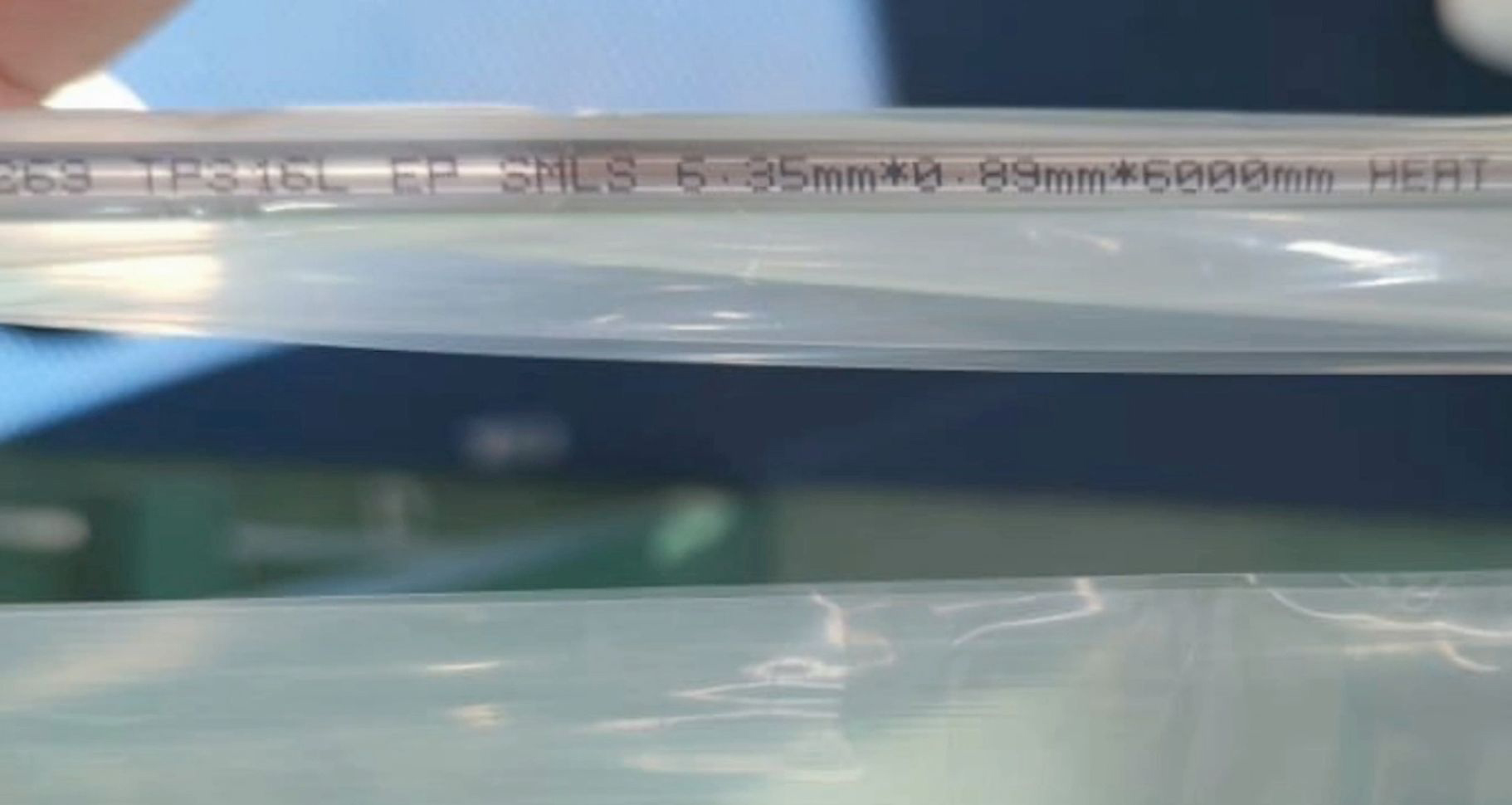

Cold rolling / Cold drawing/ Annealing/ Electropolished

Material Giredhi

TP316/316L

Packing

Imwe neimwe chubhu yakacheneswa neN2 gasi, yakavharirwa kumigumo yese, yakarongedzerwa mune yakachena kaviri-layer yemabhegi uye yekupedzisira mune yemapuranga kesi.

EP Tube Yakachena Kamuri

Yakachena Kamuri Mayero: ISO14644-1 Kirasi 5

Application

Semi-conductor/ Zviratidziro/ Chikafu · mishonga · midziyo yekugadzira bio/ Ultra yakachena yakachena pombi/ Solar magetsi kugadzira pombi/ Shipbuilding injini pombi / Aerospace injini / Hydraulic nemakanika masisitimu/ Yakachena gasi yekufambisa

Certificate of Honor

ISO9001/2015 Standard

ISO 45001/2018 Standard

PED Chitupa

TUV Hydrogen kuenderana bvunzo chitupa

FAQ

Stainless Simbi 316L electropolished chubhu imhando yesimbi isina simbi tubing iyo inoitiswa yakasarudzika pamusoro pekurapa inonzi electropolishing (EP). Heano iwo akakosha ruzivo:

- Material: Yakagadzirwa kubva 316L Stainless simbi, iyo ine yakaderera kabhoni yemukati kana ichienzaniswa ne304 Stainless simbi. Izvi zvinoita kuti irambe isingadziviriri uye inokodzera zvikumbiro pane njodzi dzekukurudzira dziripo.

- Surface Finish: Electropolishing inosanganisira kunyudza chubhu mune yemagetsi inochajiswa electrolyte solution bath. Izvi zvinonyungudutsa kusakwana pamusoro kana pazasi pechubhu, zvichikonzera kupera kwakatsetseka, kwakafanana. Iyo yemukati yemukati roughness inopupurirwa kuva nepamusoro pe10 micro-inches Ra.

- Applications:

- Pharmaceutical Industry: Inoshandiswa kune ekupedzisira-yakanyanya kuchena maapplication nekuda kwehutsanana hwayo uye kusagadzikana kwekuora.

- Chemical Processing: Sample mitsetse yekuona H2S.

- Sanitary Piping Systems: Yakanakira chikafu uye chinwiwa application.

- Semiconductor Kugadzirwa: Apo kutsetseka kwakanaka kwechubhu kwakakosha.

- Certification: Iwo anotonga zvirevo zve electropolished tubing ndeye ASTM A269, A632, uye A1016. Imwe neimwe chubhu inocheneswa neyekupedzisira-yakanyanya kuchena nitrogen, yakavharwa, uye yakapetwa kaviri muISO Kirasi 4 yakachena kamuri mamiriro.

Electropolished tubing inopa akawanda mabhenefiti:

- Corrosion Resistance: Iyo electropolishing process inobvisa kusakwana kwepamusoro, ichiwedzera kuramba kwechinhu kubva mukuora uye gomba.

- Smooth Surface Pedzisa: Iyo inokonzeresa girazi-senge kupedzisa inoderedza kupokana, zvichiita kuti zvive nyore kuchenesa nekuchengetedza. Izvi zvakakosha kune zvikumbiro mumishonga yemishonga, kugadzira chikafu, uye semiconductor maindasitiri.

- Hutsanana hwakavandudzwa: Machubhu emagetsi ane maburi mashoma uye kushata, zvichideredza njodzi yekukura kwebhakitiriya. Izvo zvakanaka kune zvikumbiro zvehutsanana.

- Yakaderedzwa Inosvibisa Adhesion: Iyo yakatsetseka pamusoro inoodza mwoyo zvimedu uye zvinosvibisa kubva pakunamatira, kuve nechokwadi chekuchena kwechigadzirwa.

- Enhanced Aesthetics: Chitarisiko chakakwenenzverwa chinotaridzika uye chakakodzera kune yepamusoro-yekupedzisira maapplication.

Electropolished tubing inowanzoshandiswa munzvimbo dzakaoma umo kuchena, kusaita ngura, uye nzvimbo dzakatsetseka dzakakosha.

| Aihwa. | Size | |

| OD(mm) | Thk(mm) | |

| 1/4″ | 6.35 | 0.89 |

| 3/8″ | 9.53 | 0.89 |

| 1/2″ | 12.70 | 1.24 |

| 3/4″ | 19.05 | 1.65 |

| 3/4″ | 19.05 | 2.11 |

| 1″ | 25.40 | 1.65 |

| 1″ | 25.40 | 2.11 |

| 1-1/4″ | 31.75 | 1.65 |

| 1-1/2″ | 38.10 | 1.65 |

| 2″ | 50.80 | 1.65 |

| 10A | 17.30 | 1.20 |

| 15A | 21.70 | 1.65 |

| 20A | 27.20 | 1.65 |

| 25A | 34.00 | 1.65 |

| 32A | 42.70 | 1.65 |

| 40A | 48.60 | 1.65 |